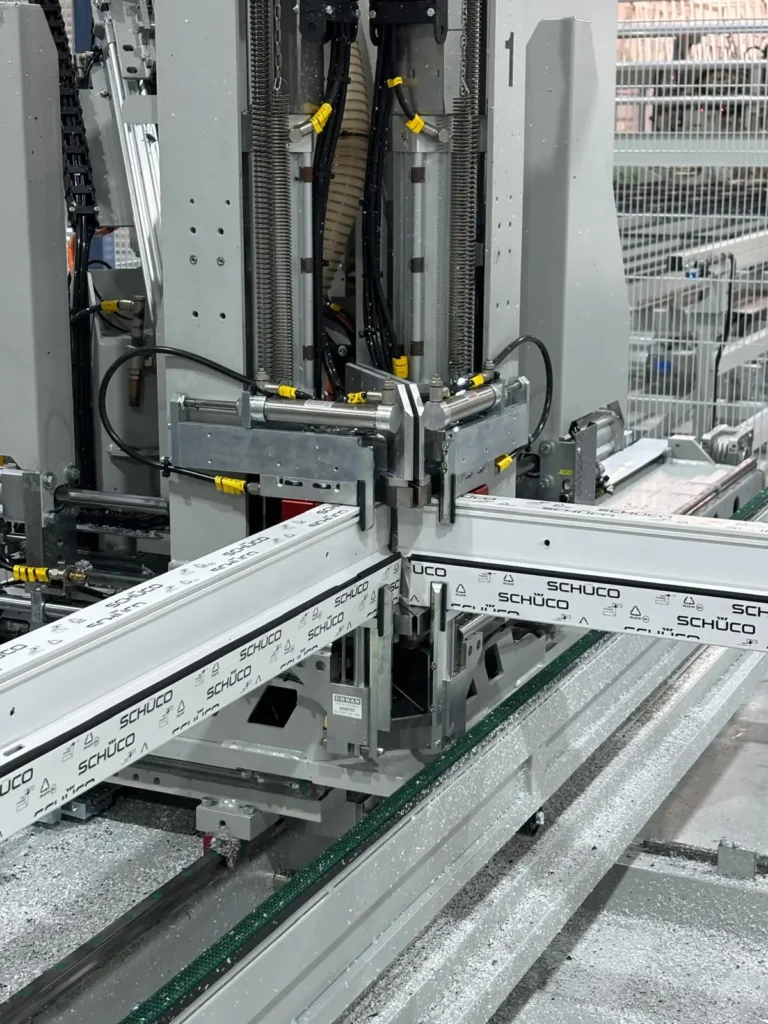

Our experience covers a wide range of brands, including Urban Machinery, HVL from Italmac, Pertici Industrie Machinery, Thorwesten, and many others in the window and door industry.

We provide fast troubleshooting and secure, expert advice to optimize production, helping you achieve better results in less time. When necessary and feasible, we can also develop new programs or make corrections to existing ones to ensure optimal performance.

Achieved significant production increases across various machines, such as raising output from 7 to 12 pieces/minute for Numalliance Frx and from 40 to 70 pieces/minute for large clips on Excenter Press.

Enhanced tooling durability by identifying and addressing manufacturing defects, extending tool replacement intervals from 20,000 to 110,000 pieces, reducing downtime and maintenance needs.

Utilized 3D simulations for tool design and optimization, ensuring consistent production speeds and smooth, uninterrupted operations.

Installed sensors and Siemens PLC systems to prevent machine crashes, improve safety, and enable seamless overnight operations without risks of breakage or errors.

Reduced reworking costs through efficient prototyping, saving time and materials for rapid adjustments and testing.

Retrofitted machines for improved accuracy, efficiency, and ease of calibration.

From welding machines to CNC machining centers, provided complete setups to streamline production lines, ensuring reliable and consistent output for your products